KITEBOARD TECHNOLOGY

“What we came up with is a kiteboard technology that is stronger than any other kiteboard construction on the market today.”

All Appletree boards are produced using a revolutionary production method that is completely unique in the surfing and kitesurfing world. This technology is developed by Appletree Surfboards and all boards are produced in our own production facility in Portugal. This way we can completely control the boards production. From acquiring the finest raw materials available to attracting the best craftsmen in the business. All custom boards are available in different strength and weight options. Check all the customizable kiteboard options.

50K CLOSED CELL FOAM

It’s Waterproof!

Every board we make starts with a foam core of our very own 50K closed cell foam. This foam is formalized exclusively for us, it is not used in any other board in the market.

The foam can withstand 50.000 kg per square meter, while staying very light, and most of all very flexible. Another plus of our 50K foam is that it is closed cell, meaning that the foam will not take in water. And the board will not blow out when it gets hot. Any small crack or ding does not need immediate repair. Eventually a repair is advised, but you can first finish your well deserved trip!

50K foam is not easy to shape, all commercially available shaping machines will have great trouble shaping it and hand shaping is not possible. At Appletree Surfboards we use our own shaping machines that we built and control ourselves. This way we can not only shape the foam, but we can also create channels and extreme contours, straight from the machine.

From the shaped foam we can go two ways: Hex-skin Carbon or Hex-skin Glass.

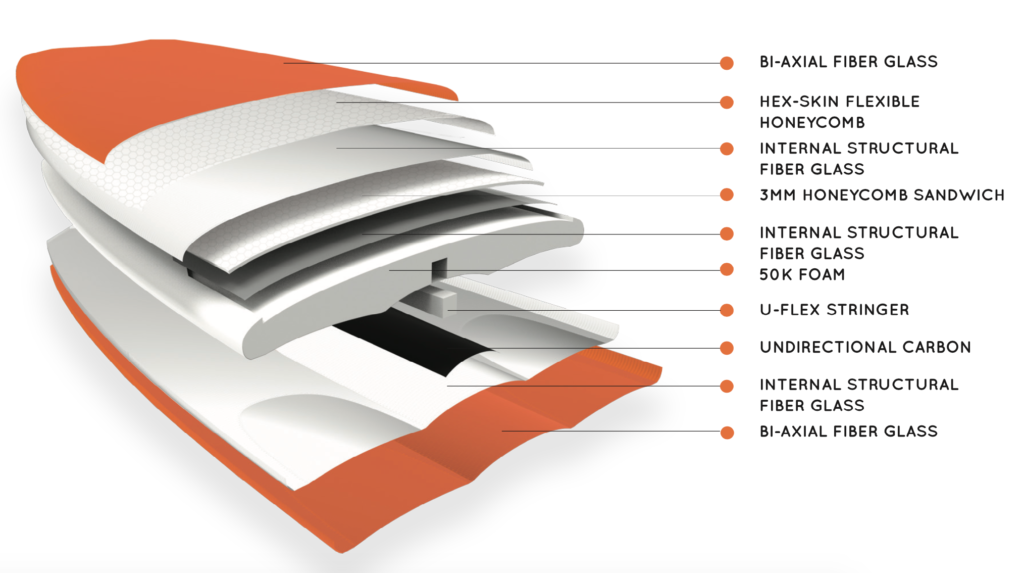

HEX-SKIN GLASS

Forgiving, flexible and strong

“Choose Hex-skin glass for a comfortable ride in waves and choppy conditions”

Our Hex-skin Glass construction consists of a 50K foam core. This foam is made exclusively for us and is 100% water- proof. The base of the board consists of three layers wrapped around the core. An internal structural fibreglass layer, a hex-skin flexible honeycomb layer and another structural fibreglass layer that is placed in a 45 degree orientation. This to keep the board as flexible as possible while making a very strong base. The bottom is left without honeycomb, again to maintain maximum flex. How your board is constructed next depends on the strength option you choose.

Extra sandwich layers can be added or another type of fibre (glass or carbon) can be chosen. The different strength options are explained in detail below. The board is now placed under a vacuum and with pressure, forcing the epoxy resin into the fibres. This way we use minimal resin and maximum fibre. Making the board super strong, yet very light. The colour is added as a pigment to the epoxy resin, coloring the entire board.

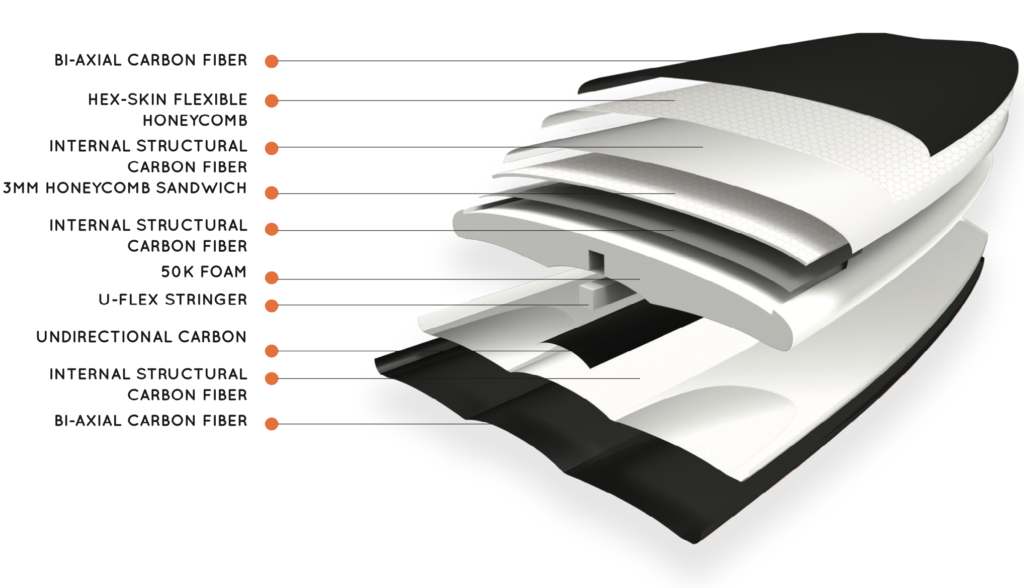

HEX-SKIN CARBON

Control, light weight and precize

“Choose Hex-skin carbon for ultimate performance and control for both wave and freestyle”

Hex-skin Carbon is similar in composition to the Hex-skin Glass boards. But instead of glass we use 100% carbon fibre, there is no glass hidden underneath the top layer of carbon. Using carbon makes the board lighter and it makes it stick to your feet even better. Because the board is so light, it flows over the chops a lot better than you might expect.

To give the carbon boards their unique look the deck and bottom is finished with a tinted resin, that can be customized. Pick your own colour or mix multiple for a truly one-of-a kind board.

STRENGTH OPTIONS HEX-SKIN GLASS

White-line build strength

This is the standard construction for kite wave surfing. Meaning true surfing with a kite. You can do the occasional freestyle jump, but in general these boards are made for the waves. The construction consists of the normal Kite+ construction explained below, but without the internal 3mm honeycomb. Instead there is an extra biaxial fibreglass layer under the front foot. The construction is more than strong enough for everyday use, and you will not ding the board easily. After some time slight heel dents may appear, this is considered normal, and it will not weaken the board.

Kite+

This is our standard custom construction, pictured above. Suits most riders for wave and freestyle. And is therefore our standard custom strength construction. Under the front foot there’s a large patch of 3mm honeycomb inlaid in the foam core, with fibreglass underneath. The core is then wrapped by a layer of structural fibre- glass in a 45 degree orientation. A second thin flexible honeycomb layer is now layered all over the deck for more impact resistance. The Kite+ strength has the perfect balance between weight, strength and flex.

Kite+ S

The same construction as the Kite+ but with all the glass in S glass. This higher quality glass is stronger and more flexible. Because of this, we can use less fibreglass and this makes the board about 15-20% lighter.

STRENGTH OPTIONS HEX-SKIN CARBON

CF- Ultralight

The lightest possible kite board. If you are after the lightest possible kiteboard construction, this is the way to go! Slight heel dents may appear over time, depending on rider’s weight and foot pressure, but the boards are ultra strong. Not really recommended for 100% freestyle, but the occasional jump is not a problem at all.

CF+

Our standard custom carbon construction, pictured above. Suits most riders for wave and freestyle and offers the right balance between weight, strength and flex. This board will last you a very long time. And in carbon fibre it is light and looks the part too!